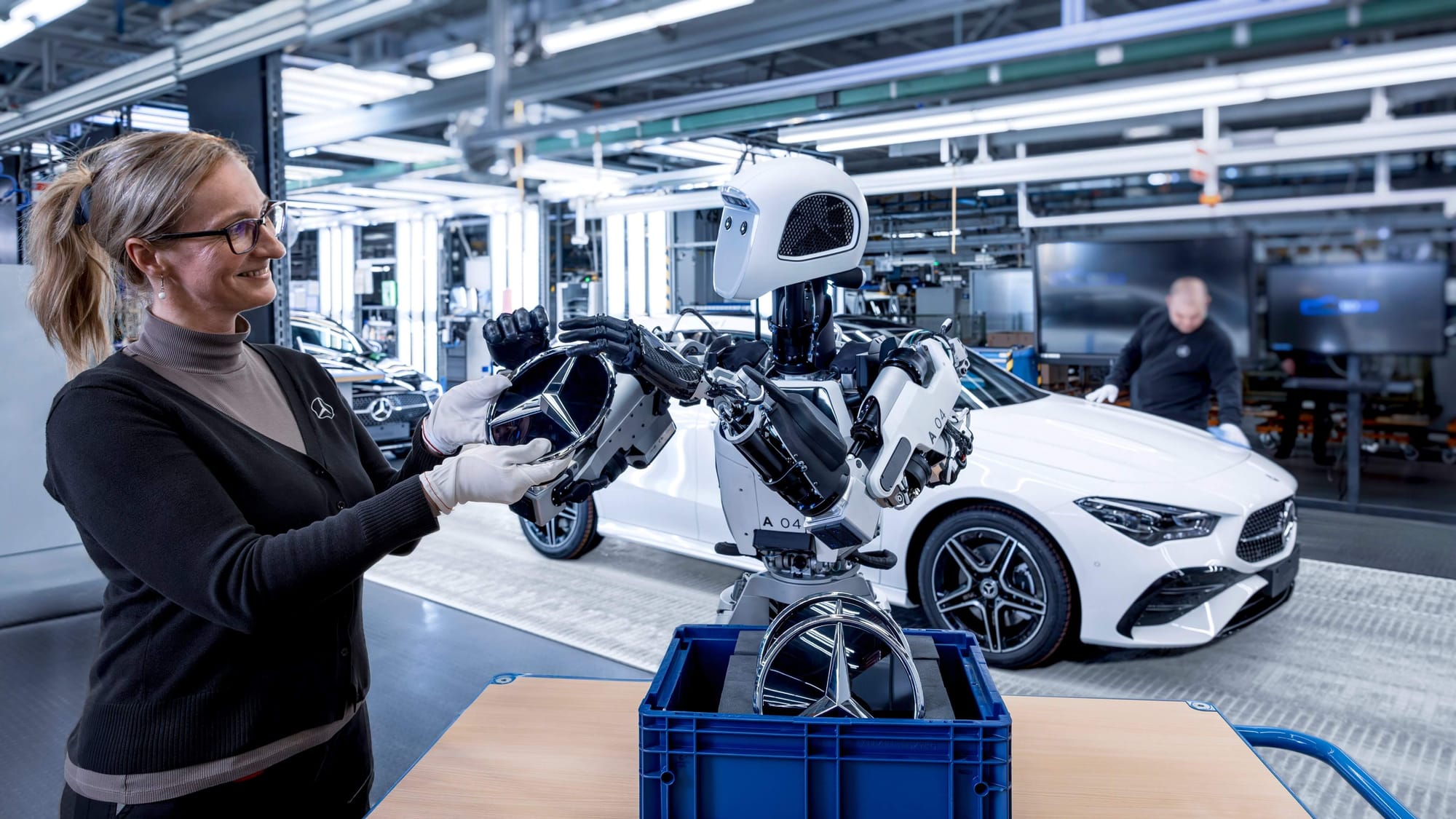

Mercedes-Benz is trialing humanoid robots for low-skill, repetitive tasks in its manufacturing facilities. The company has entered into a commercial agreement with Apptronik, a startup building next-generation humanoid robots, to pilot the use of Apollo robots in their manufacturing facilities. The partnership marks Apptronik's first publicly announced commercial deployment of Apollo and signifies Mercedes-Benz's commitment to exploring the potential of advanced robotics in automating low-skill, repetitive tasks.

According to the agreement, Mercedes-Benz will collaborate with Apptronik to identify applications for Apollo in their manufacturing processes, such as delivering parts to the production line for human workers to assemble and inspecting components. The humanoid robot will also be used to deliver totes of kitted parts later in the manufacturing process.

Standing at 5 feet 8 inches tall and weighing 160 pounds, Apollo has the ability to lift objects up to 55 pounds. Its unique force control architecture ensures safe operation around people, similar to collaborative robots. This allows Apollo to work alongside human workers while taking on physically demanding tasks.

"When we set out to build Apollo, an agreement like the one we're announcing today with Mercedes-Benz was a dream scenario," said Jeff Cardenas, co-founder & CEO of Apollo. "Mercedes plans to use robotics and Apollo for automating some low skill, physically challenging, manual labor – a model use case which we'll see other organizations replicate in the months and years to come."

The adoption of humanoid robots in factories and plants allows organizations like Mercedes-Benz to deploy robotics optimized for spaces designed for humans, avoiding the need for full-scale facility redesigns built around robots rather than people. This approach focuses on automating physically demanding, repetitive tasks for which it is increasingly challenging to find reliable workers.

Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production, Quality & Supply Chain Management, stated, "We are exploring new possibilities with the use of robotics to support our skilled workforce in manufacturing. This is a new frontier and we want to understand the potential both for robotics and automotive manufacturing to fill labor gaps in areas such as low skill, repetitive and physically demanding work and to free up our highly skilled team members on the line to build the world's most desirable cars."

The pilot program with Apptronik is part of Mercedes-Benz's ongoing efforts to evolve the future of automotive production by leveraging advancements in robotics and AI. As the industry faces labor shortages and the need for automation, humanoid robots like Apollo offer a promising solution that can work alongside human workers without requiring significant changes to existing facilities.